Excellence at the service of

of fine watchmaking

Machining, the art of

Cutting the material

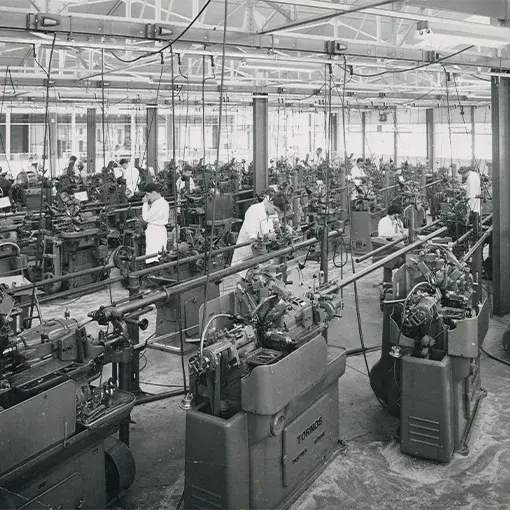

Bar turning by machines

high-precision

Bar turning is an ancestral art, preserving the expertise of a traditional machine: the cam turning machine.

This rare craft honors the mechanisms of yesteryear.

The long and meticulous adjustment times pave the way for the autonomy of these machines, which only require a breath of maintenance to last.

Bar turning is an essential technique applied to all cylindrical parts, whether they are pins, screws, pinions or spacers.

The bar turner can also cut the teeth, thus giving life to these precious mechanical components.

This process makes it possible to create parts with complex shapes and very tight tolerances, thus ensuring that they function optimally in sophisticated mechanisms. Thanks to this expertise, every detail is carefully shaped, contributing to the perfection of the mechanism of your timepiece as a whole.

Bar turning is an ancestral art, preserving the expertise of a traditional machine: the cam turning machine.

This rare craft honors the mechanisms of yesteryear.

The long and meticulous adjustment times pave the way for the autonomy of these machines, which only require a breath of maintenance to last.

Bar turning is an essential technique applied to all cylindrical parts, whether they are pins, screws, pinions or spacers.

The bar turner can also cut the teeth, thus giving life to these precious mechanical components.

This process makes it possible to create parts with complex shapes and very tight tolerances, thus ensuring that they function optimally in sophisticated mechanisms. Thanks to this expertise, every detail is carefully shaped, contributing to the perfection of the mechanism of your timepiece as a whole.

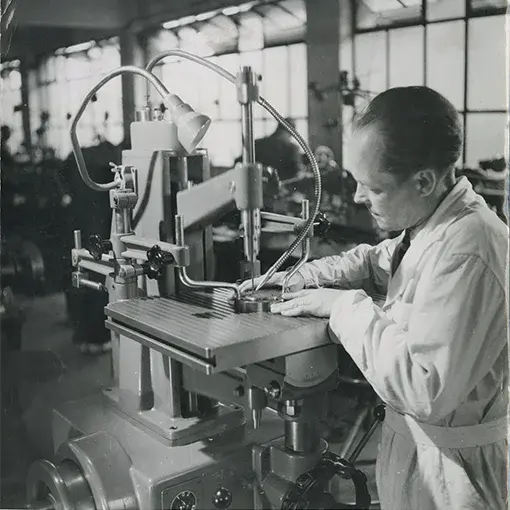

Milling, the art of shaping metal with finesse

A few “transfer machines” dating back half a century are still used for milling, but only for large series, as their meticulous and demanding adjustment can take several weeks.

This machining process is a high-quality technique that allows you to make varied and complex shapes by gradually removing material chips to obtain the desired shape.

The miller handles all flat parts such as plates, wheels, pawls, needles, etc. with extreme delicacy in order to mill them with precision.

Thus, each component of your timepiece takes shape with unparalleled finesse. These different stages of manufacture involve extremely meticulous work.

Exceptional manufacturing tolerance

In our quest for watchmaking excellence, every detail counts.

Mechanical tolerance is essential, as it defines the accepted dimensional deviations during the manufacture of components.

Together with our manufacturing partners in the Jura region, we have set tight tolerances in the micron range, i.e. 0.001 mm.

Despite the complexity of coordinating more than thirty manufacturing partners, our team rose to the challenge brilliantly.

Persée has thus become a true epic, where every micron counts in our quest for watchmaking excellence.

Let’s face it: we didn’t imagine the coordination of a

manufacturing partners, nor did we have a good understanding of the requirements of

tolerance, nor did we guess how many steps had to be taken before making aHigh-end watch box! Our team kept up the pace… Persée is an epic.

In our quest for watchmaking excellence, every detail counts.

Mechanical tolerance is essential, as it defines the accepted dimensional deviations during the manufacture of components.

Together with our manufacturing partners in the Jura region, we have set tight tolerances in the micron range, i.e. 0.001 mm.

Despite the complexity of coordinating more than thirty manufacturing partners, our team rose to the challenge brilliantly.

Persée has thus become a true epic, where every micron counts in our quest for watchmaking excellence.

Let’s face it: we didn’t imagine the coordination of a

manufacturing partners, nor did we have a good understanding of the requirements of

tolerance, nor did we guess how many steps had to be taken before making aHigh-end watch box! Our team kept up the pace… Persée is an epic.

Persée coloring treatments

Beyond its precise mechanism and elegant design, every detail of this exceptional timepiece has been thought out to captivate your gaze and arouse wonder.

Persée’s hair color treatments are the result of meticulous know-how.

Each shade, each shade is meticulously studied and applied with precision, giving life to spectacular and unique finishes.

Persée surface finishes

While there are a multitude of protective and decorative surface finishes in watchmaking, codes are nevertheless respected depending on the type of component.

This is the case, for example, with finishes such as strapping for circular parts, or stretching for “flat” parts.

A watchmaker can spend several meticulous hours cornering or polishing a single piece.

French

French English

English